Waterproofing System For Roofs & Balconies (Commercial)

Summary of application

Step 1: Pouring of the roof/balcony slab with the inclusion of Water Guard P 200.

Step 2: Application of Water Guard 5010 over the slab

Step 3: Flood Test of the roof slab

Step 4: Laying the conduit pipes and covering them with a cement sand mortar with the addition of Ressi SBR 5850 in it.

Step 5: Screeding in slope with the inclusion of Ressi SBR 5850 and Silmix in the roof screed mix.

Step 6: Making of chamfers with a cement sand mortar comprising of Ressi SBR 5850 and Silmix .

Step 7: Finishing of the screed as required.

Detailed description

Commercial Projects usually require the best price to performance ratios of products. It is for this reason Ressichem presents a variety of products packaged together as a systematic solution for the execution of waterproofing systems for cost-effective projects.

The proposed system not only provides the most economical solution for waterproofing but durable and long lasting as well.

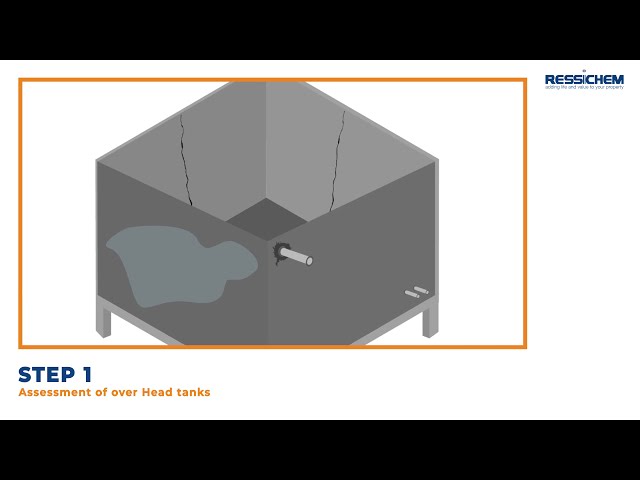

Step 1: Pouring of the slab.

It is important that good quality concrete is used when pouring an area as critical as roofs and balconies. Water Guard P 200 is the recommended admixture to be used with the cement of the concrete in this case. It is recommended to use 1 KG of Water Guard P 200 admixture with every 50 KG Bag of cement (Please refer to product datasheet for further details). Once the concreting works have been executed, it is recommended to have the parapet walls of the roof slab and balconies erected and plastered prior to the application of water Guard 5010 and other subsequent materials.

Step 2: Application of Water Guard 5010 over the slab

Once the roof slab has been casted, it is essential to apply the waterproofing coating of Water Guard 5010. It is a 2-component flexible cementitious copolymer coating ideally designed as a waterproofing coat over concrete and other cementitious surfaces to resist positive water ingress. It is essential to apply water Guard 5010 Correctly, it is recommended to apply 2 coats of the material in right angled directions. If the first coat is applied top to bottom, the second coat should be applied in a left to right direction (Please refer product datasheet for further information).

Step 3: Flood Test of the roof slab.

Once the coating of water Guard 5010 has been dried, it is recommended to conduct a flood test over the roof slab by filling it with 3 to 4 inches of water for at least 48 to 72 hours. The leakage points after the flood test should be rectified using appropriate means and the flood test should be repeated until all the leakage points have been rectified.

Step 4: Conduit / Utility pipes over the roof slab.

Once the flood test over the slab has been successfully conducted, the utility pipes of electric, gas and plumbing are usually passed through the slab for various areas of the building. Once these lines are laid, it is recommended to cover them up with a cement sand mortar material comprising of Ressi SBR 5850. The recommended ratio is 1:4 (Cement: Sand) with the addition of 1 KG of Ressi SBR 5850 Added for every 50 KG Bag of cement. It Is recommended to fully cover these lines with the material with at least a thickness of 4mm to 8mm. Once the utility lines have been properly covered, it is recommended to coat over the material with at least 2 coats of Water Guard 5010 to ensure proper waterproofing of the utility lines.

Step 5: Screeding of the roof slab.

After properly protecting and covering the utility lines, a screed is usually poured over the roof slab. It is recommended to use good strong mix design for the screed. It is also recommended to add Ressi SBR 5850 along with the addition of Silmix within the mix of the screed. The recommended dosage of Ressi SBR 5850 and Silmix is 1 Ltr each for every 50 KG Bag of cement used in the placement of floor screed over the roof and balcony slab. It is to be strictly ensured that the screed is placed in a slope moving towards the water drainpipes of the slab. If the slopes are not properly maintained, the functioning life of the slab will be reduced drastically and will cause many issues within the lifetime of the slab. Proper screeding in slope moving towards water drains is one of the most important elements of the waterproofing system for roofs and balconies. For larger areas proper panel grooves should be given in the screed at regular intervals to avoid cracks forming in the screed over time.

Step 6: Making of chamfers

Once screeding works have been completed it is recommended to make chamfers between the parapet walls and the floor screed. The material recommended for making the chamfers in this case is a combination of Ressi SBR 5850 and Silmix. Both these materials are added as 1 Ltr each with each 50 KG bag of cement as an additive to promote bonding and waterproofing of the chamfers. The chamfers should be at least 4 inches tall and 4 inches wide along the entire area intersecting the parapet walls and floor screed. This is also to be ensured for skylight openings and the parapet walls of those as well.

Step 7: Finishing of the screed

Once the screed has been laid, cured, and dried out completely, it can be finished with a suitable material such as tiles, marble, or any other finish as per requirement. The screed itself can also be left without finishing if no further finish is required.

Note:

This entire system is designed by sandwiching the coating of Water Guard 5010 between the slab and the screed. Water Guard 5010 can also be applied after the screeding of the slab as well. However, for prolonged life of the coatings, it is usually recommended to sandwich them for long term waterproofing durability of roofs and balconies.

What is a Chamfer?

Is a transitional edge between two faces of an object. Sometimes defined as a form of bevel, it is often created at a 45° angle between two adjoining right-angled faces. ( Wikipedia).

In waterproofing systems, making a chamfer is of great significance. Water normally gets stuck in areas which have sharp corners of 90° & on several occasions the leakage of water occurs from this the sharp angle of the water retaining bodies or areas where significant waterproofing is required. To minimize the effect of this, a chamfer is usually created to make sure that there are no sharp angles in the structure to minimize the effect of water coming in & out of the structur

System Summary

ROOFS & BALCONIES (COMMERCIAL)

A: Slab with the inclusion of Water Guard P 200

B: Water Guard 5010

C: Conduit / Utility Pipes

D: Cement and sand mortar with Ressi SBR 5850 and coating of Water Guard 5010

E: Floor Screed with Ressi SBR 5850 and Silmix

F: Chamfer with Ressi SBR 5850 and Silmix

G: Final Floor Finish

H: Drain Point