Waterproofing System For Overhead Tanks (Commercial)

Summary of application

STEP 1: Pouring of the concrete with the addition of Water Guard Crysta Admix 103.

STEP 2: Filling and repairing of the concrete voids with a mortar made with the inclusion of Ressi SBR 5850 and Silmix.

STEP 3: Application of Water Guard Crysta Coat 102 over the prepared concrete surfaces.

STEP 4: Making of internal chamfers with a mortar comprising of Ressi SBR 5850 & Silmix and coat the chamfer with Water Guard Crysta Coat 102.

NOTE: Do flood Test after Step 4.

STEP 5: Internal and External plastering of the OH Tank with the addition of Silmix and Ressi SBR 5850 in the plastering mortar.

STEP 6: Internal coating over the plastered surface of Water Guard 5010.

Detailed description

When it comes to the waterproofing of overhead tanks at commercial projects, we believe in having a system which has an optimum cost to performance ratio. It is for this reason we have a variety of products to cater to the waterproofing needs of overhead tanks for commercial projects. We also believe that there should not be much maintenance of the overhead tank during its useful life.

It is essential that the concrete pouring of the overhead tank should be planned accordingly so that there is not much maintenance work to be done to the tank once it is in operation.

When planning for the overhead tank, it is important to make sure that the water pipe sleeves are carefully planned within the formwork to have proper water inlet and outlet points. If there is breaking or hacking of the concrete after the overhead tank has been casted, it becomes diffcult to stop the water leakage from pipe inlets and outlets.

It is also essential to use potable water friendly materials in the waterproofing of the tank so that there are no adverse chemical effects, & the stored water remains fit for human use.

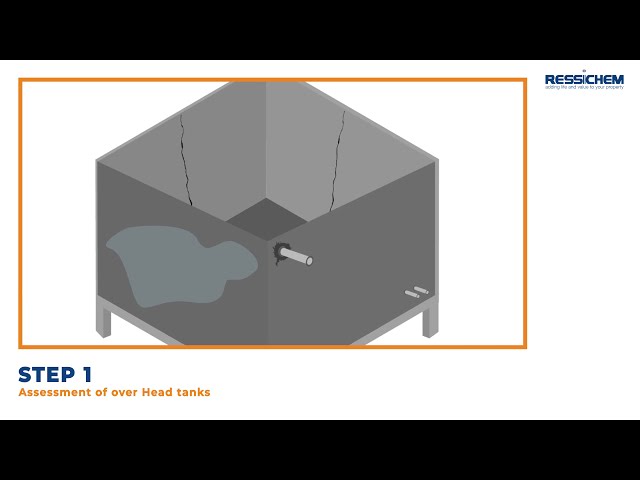

Step 1: Pouring of the concrete and form work.

Good quality formwork should always be used when pouring an area as sensitive & essential as the overhead tank. It is essential to make note & plan of all the pipe inlets & outlets within the form work to avoid leakage problems from these points when the overhead tank is in use. The concrete to be poured should be of exceptional quality. The addition of a good integral waterproofing admixture is essential to make concrete as water resistant as possible. Water Guard Crysta admix 103 is recommended as an integral waterproofing admixture for the pouring of overhead tank concrete in this case. 1 KG of Water Guard Crysta admix 103 is the recommended dosage per 50 KG bag of cement for the pouring of concrete. It is also essential that all the concrete should be poured in one go to avoid the formation of any joints between the base & the walls of the overhead tank.

Step 2: Filling & repairing of the concrete voids.

Once the formwork has been removed. It is essential to repair all the defects of the concrete with a suitable repairing material. A combination of Ressi SBR 5850 with a mortar of cement and sand at a suitable ratio of 1:4 (Cement: sand) can be used as an appropriate repairing material for the minor concrete defects and the voids created by the metal strips (Incase wooden formwork has been used). Once the concrete is repaired & of a sound nature subsequent treatment of various waterproofing materials can be done over the concrete surface of the overhead tank. The ratio of Ressi SBR 5850 to be used in this case would be 1 KG of Ressi SBR 5850 with every 50 KG bag of cement.

Step 3: Application of Water Guard Crysta Coat 102 over the prepared concrete surfaces.

Water Guard Crysta Coat 102 is a crystalline waterproofing slurry coat which is to be coated over the prepared concrete surface on all the exterior & interior surfaces of the overhead tank. At least two coats of Water Guard Crysta Coat 102 are recommended & are to be applied in right-angled patterns. If the first coat is applied in top to bottom pattern the second coat should be applied in left to right patterns. It is recommended to make sure that all the concrete that has been casted internally & externally is coated properly with Water Guard Crysta Coat 102 (Forfurther application guidance, please refer to the product datasheet).

Step 4: Making of internal chamfers.

It is recommended to make internal chamfers at the base & on all the walls of the overhead tank. All angles of 90° in the base & the walls of the tank should be neutralized. The chamfer should be at least 6 inches tall & wide throughout the all the corners of the overhead tank. (Please see the illustration for better understanding). The material recommended in this case for the making of chamfer for the overhead tank is a cement sand mortar with the inclusion of Ressi SBR 5850. The ratio of the cement sand mortar in this case would be 1:4 (Cement: sand). The amount of SBR to be used in this case would be 1 Ltr of Ressi SBR 5850 to be used with every 50 KG bag of cement used in the making of the chamfer. Once the chamfers have been completed, they too should be coated with a crystalline coating of Water Guard Crysta Coat 102.

Flood test

Note: Once the chamfers work has been completed & coating of Water Guard Crysta Coat 102 has been done both internally & externally over all the concrete surfaces, it is recommended to have a flood test for 72 hours of the overhead tank (Filling up the tank with water) to check if there are any leakages in the tank, the points with leakage should be rectified prior to plastering. It is essential that all pipe inlets & outlets should be checked thoroughly for any water leakage at this time.

Step 5: Internal & External Plastering

Once all the chamfer work has been properly executed, the inner & outer surface of the overhead tank should be ready to plaster. It is recommended to use Silmix & Ressi SBR 5850 as mortar admixtures to make sure that there are no cracks in the plaster and the plaster itself is water-repellent. It is recommended to add 1 Liter of Silmix along with 1 Ltr of Ressi SBR 5850 with every bag of cement used for the plastering of internal & external areas of the overhead tank. It is to be ensured that the internal plaster of the overhead tank should be finished slightly rough, exposing some grains using a foam (Foam finish plaster). This will provide a good key for the subsequent coating of Water Guard 5010.

Step 6: Internal coating of water Guard 5010

Once all the internal and external plastering works have been completed, it is recommended to apply at least 2 coats of Water Guard 5010 in all the internal areas of the overhead tank. It is recommended that both the coats are applied in opposite right-angled directions. If the first coat is applied with vertical brush strokes, the second coat is to be applied with horizontal brush strokes. (For further application & mixing guidelines of Water Guard 5010, please refer to the technical datasheet of the product).

What is a Chamfer?

Is a transitional edge between two faces of an object. Sometimes defined as a form of bevel, it is often created at a 45° angle between two adjoining right-angled faces. ( Wikipedia). In waterproofing systems, making a chamfer is of great significance. Water normally gets stuck in areas which have sharp corners of 90° & on several occasions the leakage of water occurs from this the sharp angle of the water retaining bodies or areas where significant waterproofing is required. To minimize the effect of this, a chamfer is usually created to make sure that there are no sharp angles in the structure to minimize the effect of water coming in & out of the structure.